Tesla aluminum body repair presents unique challenges due to the material's malleability, demanding precise straightening and skilled handling. Modern techniques like laser-guided straightening and robotic welding, aided by CAD software, transform repairs, preserving structural integrity and aesthetic appeal of Tesla vehicles while minimizing damage. Specialized collision centers with advanced technology are crucial for optimal outcomes, ensuring performance and value retention.

Tesla’s innovative use of aluminum body construction in their vehicles presents unique advantages but also specific challenges during repair. This article delves into the intricacies of Tesla aluminum body repair and frame straightening, exploring the distinct considerations compared to traditional steel frameworks. We examine common issues, from corrosion to misalignment, and highlight advanced techniques that ensure precise restoration. Understanding these methods is crucial for professionals aiming to master Tesla aluminum body repair.

- Understanding Tesla Aluminum Body Construction

- Common Issues and Challenges in Repair

- Advanced Techniques for Frame Straightening

Understanding Tesla Aluminum Body Construction

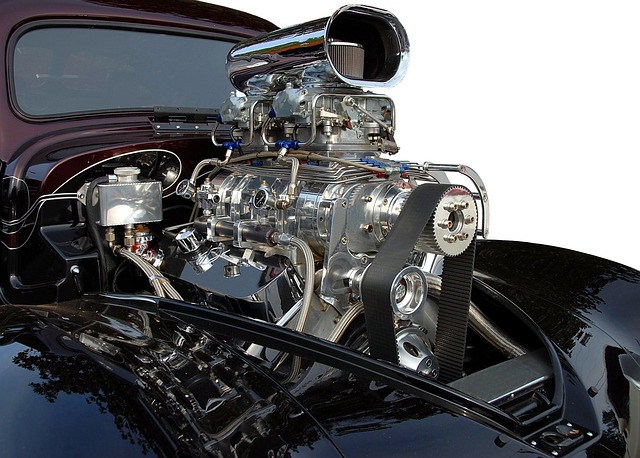

Tesla’s use of aluminum in their vehicle construction offers both advantages and unique challenges when it comes to body repair and frame straightening. The brand’s cars are known for their lightweight, durable frames, which contribute to improved performance and efficiency. However, working with aluminum requires specialized knowledge and equipment due to its distinct properties. Unlike traditional steel bodies, aluminum can deform and retain different shapes during impact, making precise straightening techniques essential for restoring structural integrity.

When a Tesla experiences damage, especially in a collision, it’s crucial to approach aluminum body repair with expertise. Reputable collision centers equipped with advanced technology are adept at handling these repairs, ensuring the vehicle returns to its original specifications. From specialized tools for straightening to expert car paint services, these centers cater to Tesla owners, guaranteeing not just structural soundness but also the vehicle’s aesthetic appeal.

Common Issues and Challenges in Repair

Tesla aluminum body repairs present unique challenges compared to traditional steel or metal frameworks. One of the primary issues is the material’s inherent properties; aluminum is known for its malleability and susceptibility to denting, which can be more difficult to rectify than with other metals. Even minor impacts or scratches can leave noticeable marks, requiring meticulous techniques and specialized tools for effective straightening.

Additionally, the intricate design and precision engineering of Tesla vehicles demand a high level of skill and accuracy during repair. Auto body repairs on these models often involve complex panel configurations and integrated components that need to be carefully handled to maintain the vehicle’s structural integrity and aesthetic appeal. Finding an auto repair shop with experienced technicians who specialize in Tesla aluminum body repairs is crucial to ensure the best outcomes and preserve the car’s overall performance and value.

Advanced Techniques for Frame Straightening

In the realm of Tesla aluminum body repair, frame straightening has evolved into a sophisticated art. Modern techniques go beyond traditional methods, employing advanced technology to ensure precision and minimal damage to the lightweight yet robust aluminum construction common in Tesla vehicles. One such method is laser-guided straightening, which uses high-precision lasers to measure and adjust panel alignment with unprecedented accuracy, preserving the vehicle’s structural integrity and aesthetic appeal.

Additionally, robotic welding systems have revolutionized fleet repair services and auto body services for Tesla models. These robots ensure consistent, seamless welds, crucial for maintaining the vehicle’s overall performance and safety. Moreover, advanced computer-aided design (CAD) software allows technicians to digitally manipulate and analyze frame damage, facilitating complex repairs with remarkable efficiency. This technology not only speeds up vehicle repair services but also enhances the quality of work, making it a cornerstone of professional vehicle repair services for Tesla owners.

Tesla’s innovative use of aluminum body construction presents unique advantages, but it also comes with specific challenges during repairs. By understanding the intricate design and employing advanced techniques like precision frame straightening, specialized technicians can effectively address common issues. This ensures that Tesla vehicles retain their structural integrity, performance, and distinctive aesthetic appeal over time. For optimal Tesla aluminum body repair, staying abreast of these cutting-edge methods is key.