Tesla aluminum body repair poses unique challenges due to aluminum's malleability compared to steel. It requires specialized techniques like precision welding and advanced fabrication for structural integrity. Expert car paint services match original finishes, while specialized shops use CAD software, hydraulic presses, and modern spray painting to preserve both structural and aesthetic excellence.

In today’s automotive landscape, Tesla aluminum body repair has emerged as a game-changer, reflecting the brand’s commitment to lightweight, durable designs. However, this innovative approach presents unique challenges. From understanding the peculiar properties of aluminum, such as its corrosion resistance and malleability, to navigating complex vehicle design and precision repair, specialists must master specialized tools and techniques. This article delves into these top challenges, offering insights for professionals in the Tesla aluminum body repair field.

- Unique Material Properties and Their Challenges

- Complex Design and Precision Required

- Specialized Tools and Techniques Needed for Repair

Unique Material Properties and Their Challenges

Tesla aluminum body repair presents unique challenges due to the distinct material properties of aluminum compared to traditional steel bodies. Aluminum is lighter and more corrosion-resistant, offering significant benefits in fuel efficiency and vehicle performance. However, this lightweight nature also means it’s more susceptible to denting and deforming during collisions or accidents. Repairs often require specialized techniques like precision welding and advanced fabrication methods to ensure structural integrity and maintain the car’s original appearance.

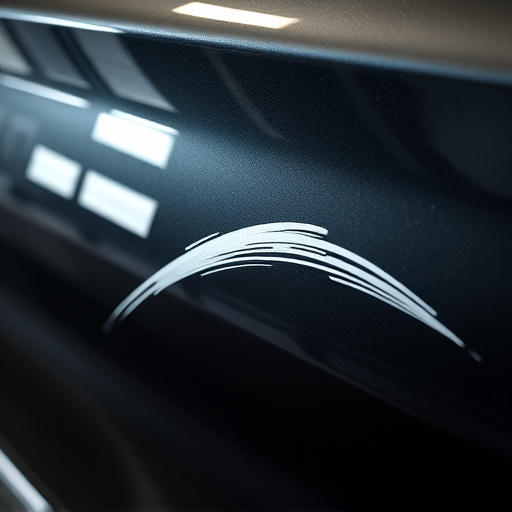

Another challenge lies in matching the finished repair with the vehicle’s original paint job. Since aluminum expands and contracts differently from paint, precise alignment is crucial to avoid visible gaps or waves in the final coat. Skilled technicians need to employ expert car paint services, carefully addressing issues like surface preparation, priming, and painting to achieve a flawless, seamless finish that blends perfectly with the rest of the vehicle. This level of detail is essential for Tesla owners who demand both structural integrity and cosmetic excellence in their aluminum-bodied cars, reflecting the brand’s commitment to innovation and quality in collision repair.

Complex Design and Precision Required

The process of Tesla aluminum body repair is a delicate art that demands exceptional skill and precision due to the intricate designs and lightweight construction of Tesla vehicles. Each panel on a Tesla must fit perfectly with the surrounding components, contributing to the overall aerodynamics and aesthetics of the car. This level of complexity requires highly specialized knowledge and advanced tools to ensure accurate alignment and seamless finishes.

The challenge lies in achieving perfect precision while working with aluminum, a metal known for its malleability and corrosion resistance. Unlike traditional steel bodies, aluminum panels can be more challenging to straighten and repair without leaving visible traces or compromising the structural integrity of the vehicle. Auto collision centers specializing in Tesla repairs must invest in state-of-the-art equipment capable of handling these intricate tasks, ensuring that every dent, scratch, or damage is addressed with meticulous care, ultimately delivering top-notch collision repair services for these advanced electric vehicles.

Specialized Tools and Techniques Needed for Repair

In the realm of Tesla aluminum body repair, one faces unique challenges that demand specialized tools and techniques. The intricate design and construction of Tesla vehicles necessitate precision and expertise to ensure structural integrity and aesthetic excellence after any repair work. Unlike conventional steel bodies, aluminum presents distinct considerations, including its lightweight yet delicate nature, which requires a tailored approach.

Professionals in the field rely on advanced equipment such as computer-aided design (CAD) software for accurate measurements and adjustments, as well as specialized tools like hydraulic presses and precision cutting devices. Moreover, car paint services play a vital role, employing state-of-the-art spray painting techniques and high-quality paints to match the vehicle’s original finish. Engaging a reputable car body shop with expertise in Tesla aluminum body repair is crucial for achieving top-notch results, ensuring the vehicle retains its structural strength and visually stunning appearance, akin to a masterfully restored car body.

Tesla aluminum body repair presents unique challenges due to the material’s distinct properties, intricate design demands, and specialized tools required. Understanding these obstacles is crucial for efficient and effective repairs, ensuring the longevity and aesthetic integrity of Tesla vehicles. By mastering these aspects, professionals can navigate the complexities of Tesla aluminum body repair, delivering top-notch results that meet the high standards expected by Tesla owners.