Tesla aluminum body repair presents unique challenges due to the material's superior strength-to-weight ratio and corrosion resistance, making it ideal for efficient electric vehicle manufacturing but complicating damage repairs. This process requires specialized skills, tools, and techniques for tasks like dent removal, panel alignment, and welding, ensuring structural integrity and aesthetic precision while preserving the lightweight yet sturdy nature of aluminum. Matching intricate colors and finishes is a major concern, necessitating skilled technicians with specialized equipment to maintain Tesla vehicles' distinctive appeal post-repair.

In the realm of automotive restoration, Tesla aluminum body repair presents unique challenges. This article delves into the intricate complexities of repairing Tesla vehicles with aluminum bodies, highlighting the importance of understanding their distinctive properties. From specialized tools and techniques to matching color and finish—a significant concern for Tesla owners—we explore the key obstacles in this game-changing process. Discover how professionals navigate these hurdles to ensure top-tier results.

- Unique Properties of Aluminum and Their Impact on Repair

- Specialized Tools and Techniques Required for Tesla Aluminum Body Repair

- Challenges in Matching Color and Finish: A Major Concern for Tesla Owners

Unique Properties of Aluminum and Their Impact on Repair

Aluminum, a lightweight yet robust metal, offers unique properties that both benefit and challenge Tesla aluminum body repair work. Its superior strength-to-weight ratio makes it an ideal choice for automotive manufacturing, including electric vehicles like Teslas, where efficient energy transfer and reduced weight are paramount. However, this very characteristic also means that when damage occurs, auto body work can be more complex. Aluminum is known for its corrosion resistance, which is a significant advantage in preventing rust and maintaining the car’s aesthetic appeal over time. Yet, during the repair process, ensuring proper bonding of replacement panels or parts is crucial due to its smooth surface finish, requiring specialized techniques and materials.

The non-ferrous nature of aluminum also sets it apart from steel in terms of how it deforms and reacts to heat. This unique behavior during a car collision repair can make straightening and aligning more intricate. Professionals must carefully consider the metal’s memory and thermal properties to restore the vehicle to its pre-accident condition, ensuring structural integrity without compromising the original design and sleek appearance for which Teslas are renowned in the car body restoration process.

Specialized Tools and Techniques Required for Tesla Aluminum Body Repair

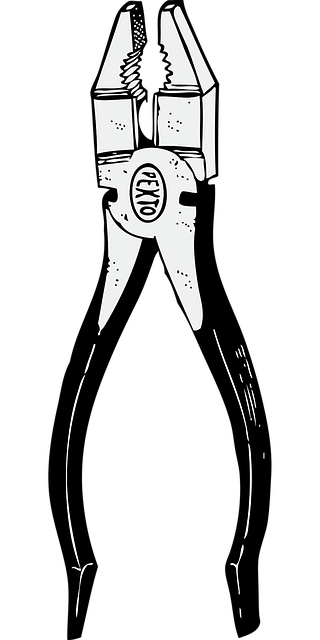

The Tesla aluminum body repair process demands a unique set of skills and specialized tools that go beyond conventional vehicle repairs. This is primarily due to the distinct properties of aluminum, which requires specific techniques to ensure structural integrity and aesthetic precision. Professionals in car body shops handling Tesla models must be equipped with advanced knowledge and equipment for this specialized task.

One key challenge lies in the use of unique tools designed for aluminum body repair, which differ from those used in standard auto painting or vehicle collision repairs. These tools are crucial for tasks such as dent removal, panel alignment, and welding, ensuring minimal damage to the intricate designs and precise dimensions of Tesla vehicles. The precision required in these processes is magnified by the lightweight yet sturdy nature of aluminum, making it a game-changer in modern car manufacturing, especially for electric vehicle models like Teslas.

Challenges in Matching Color and Finish: A Major Concern for Tesla Owners

Tesla aluminum body repair work presents unique challenges, particularly when it comes to matching the color and finish of the vehicle’s exterior. Tesla owners take pride in their cars’ sleek, modern design, and any deviation from the original specifications can be a source of frustration. The intricate paint jobs on Tesla vehicles, often featuring advanced colors and finishes, require precise techniques and specialized equipment to replicate accurately.

The challenge lies in achieving a seamless blend that matches not only the color but also the glossy or matte finish, ensuring no visible gaps or inconsistencies. This meticulous process demands skilled technicians who understand the nuances of aluminum panel repair and painting. Using high-quality materials and following strict quality control measures are essential to address this major concern for Tesla owners, guaranteeing their vehicles maintain their distinctive aesthetic appeal after any repair work.

Tesla aluminum body repair presents unique challenges due to the material’s exceptional yet peculiar properties. The process demands specialized tools and techniques to ensure precision and quality, which can be a hurdle for non-expert repairs. Among these, matching color and finish accurately is a significant concern for Tesla owners, as it determines the vehicle’s aesthetic appeal and resale value. Understanding these challenges is crucial for both owners and professionals aiming to excel in Tesla aluminum body repair work.